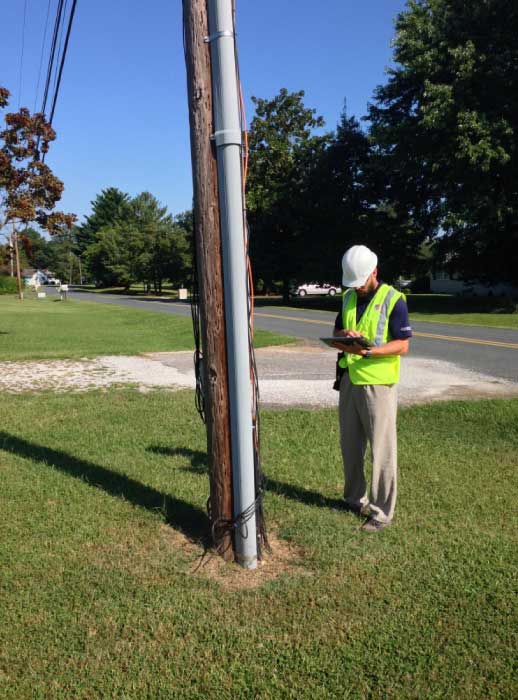

GROUNDLINE POLE INSPECTIONS

Our professionally trained field technicians perform a combination of inspections including Visual, Sound and Bore Inspections and full or partial Excavation when determining if decay or insects are present. Certified crews utilize Internal/External Treatments to maintain and preserve the strength of your assets. All data and GIS information is captured and stored while in the field using the FDC. This tool allows the RAMS team to report and share information with you with a high degree of accuracy and ease.

OVERHEAD FEEDER INSPECTIONS

With a proven track record and the ability to perform conditional assessment inspections on overhead assets, RAMS can generate engineering reviews and recommendations that lead to improved SAIDI/SAIFI and CAIDI which can provide safer and more reliable systems.

CONTACT VOLTAGE INSPECTIONS

Through IEEE recommended and approved methods of evaluating overhead assets, padmounts, underground, and substation facilities, RAMS provides a contact voltage program which includes updated GIS records for accurate locations of your systems assets.

PADMOUNT/SUB-SURFACE INSPECTIONS

Our specialty padmount crews perform inspections of padmount and subsurface equipment, ensuring that your assets our safe and reliable. Our proficiency in painting padmount devices is un-paralleled in the industry, making RAMS a preferred contractor. Inspections include integrity evaluations, GIS records, labeling/stenciling, rust repair, patching, painting, photos, contact voltage, IR and Ultrasound NDT.

ULTRASONIC & INFRARED INSPECTIONS

Proactive ultrasonic and infrared inspection has become an industry leading standard and has the potential to reduce risk, increase operational safety, and increase the efficiency of your systems. Ultrasonic Inspection is a useful and versatile NDT method and is sensitive to both surface and subsurface discontinuities. The depth of penetration for flaw detection or measurement is superior to other NDT methods. Using this cutting edge technology certified RAMS field technicians perform Predictive/Preventative Maintenance inspections partnering a mobile based visual scan with high end ultrasonic equipment. Field proven ultrasound techniques assure the detection of the most up to the minute acoustic signatures. Infrared Inspection is a proven, non-destructive technology for early detection of impending failures in electrical systems. Our certified (Level I-III) thermographers perform predictive and preventative Infrared NDT Assessments on overhead assets, padmounts, underground, and substation facilities. These ultrasonic and infrared assessments can be tailored to your specific target values or normal operating ranges.

SUBSTATION INSPECTIONS

We provide highly trained personnel to perform IR, Ultrasonic, and visual reliability and conditional assessments of substation facilities and equipment including perimeter integrity.

STORM PATROL AND DAMAGE EVALUATION

Not rain, sleet, nor snow can keep us from protecting your systems and customers in times of need. Our crews are always packed and ready to respond when disaster strikes and the power goes out. Storm response allows us to provide the your utility with essential additional crew and resources to perform “bird-dogging”, damage assessment, repairs, and post storm evaluations to aid restoration efforts. Our RSC allows us to upload feeder maps digitally, record and transfer data, take digital photos and collect GIS records for you in the most critical hours.